Best 3D Printer 2020 under $500

Buy best 3D Printer 2020 under $500

Dual extruder 3D printer -- Which can be used with two materials for printing at one time, has special advantages in applications, realizes the functions and applications that single extruder 3D printer cannot.

1 Water-solutable support (PVA): For some models with complex structures, the support of ordinary filament is difficult to remove. The support part composed of PVA can be completely dissolved in water and is non-toxic and tasteless. Therefore, it can be easily removed from the model by using water-soluble support.

Application case: Conformal cooling pipes-due to structural requirements, conformal cooling pipes are often curved. If all this model is printed with PLA, it is difficult to physically remove the printed supports, and only water-soluble supports can be used .

2 Two-material model: Some special models require a combination of two materials. For example, one nozzle prints with 98A TPU, and the other prints with 90A TPU.

Application case: Orthopedic insole model. Doctors need to design the insole according to the requirements of each patient. Different stress points need to be printed with TPU of different hardness.

3 Two-color model: Some models need to be printed in two colors to achieve special visual effects.

Application case: Stereo vision training model, which needs to be printed with two gray values for visual testing and training.

Of course, the dual extruder 3D printer also has some shortcomings and difficulties to be solved.

1). The machine is expensive. At present, many dual extruder machines on the market are more expensive, especially the relatively stable dual extruder machines.

2). Filament is expensive. The price of water-soluble filament(PVA) is about 3 times more expensive than PLA.

3). The machine is unstable, which is related to disadvantage 1). Cheap machines are unstable, and stable machines are expensive.

4). The printing area is reduced. Because more parts occupy the original area, the working area of the dual extruder is reduced compared to the single extruder with the same machine size.

1). Machine stability, makes the switching of dual extruder more stable.

2). The stickiness of the two filament, such as the problem that PVA cannot stick to PLA when printed, this problem needs to be improved in terms of filament.

3). Printing quality. At present, more dual extruder machines will cause the two filament to be mixed with each other, resulting in lower quality printing .

The current main categories of dual extruder 3D printers:

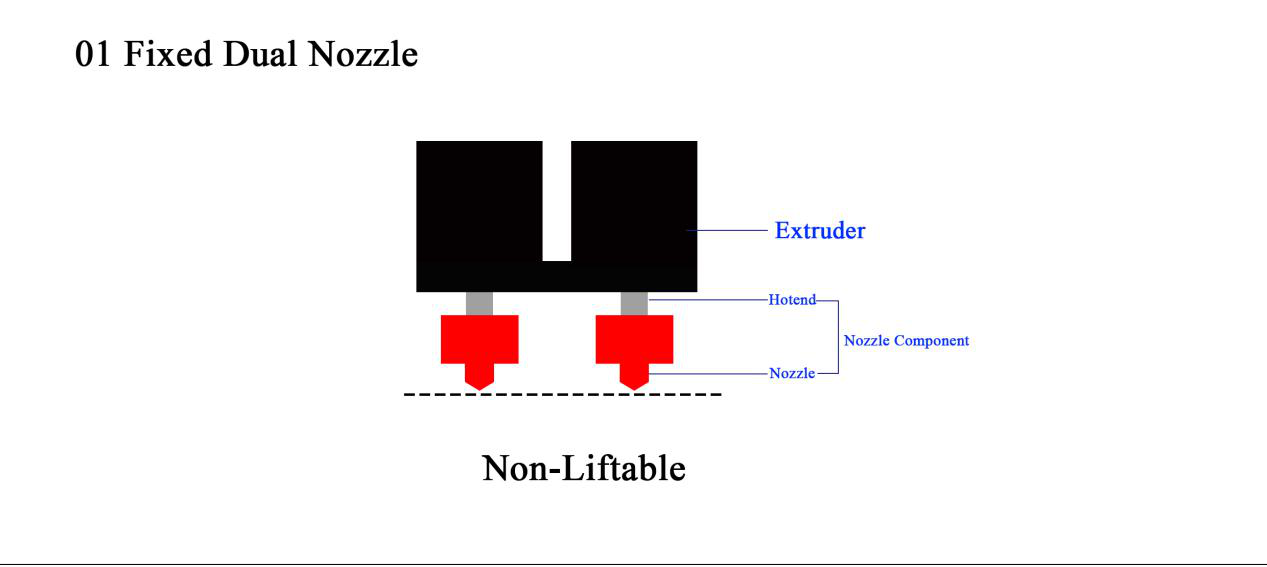

1 Fixed dual nozzle, both of the nozzles cannot be raised and lowered.

2 Liftable double nozzle, and one of the nozzle can be controlled by a steering gear or other mechanical movement structure.

3 Independent nozzle and extruder(IDEX), installed on the same axis,but the two step motors are moving independently.

4 Dual extruder single nozzle, there are two extruders, but only one nozzle, only one filament can enter the nozzle for printing at a time.

5 Dual extruder mixed nozzle, similar to 4, but supports two filaments into the nozzle at the same time for printing.

Advantages and disadvantages of various dual extruder 3D printers:

Type | Advantage | Disadvantage |

Fixed dual nozzle | Simple structure and cheap | Poor print quality |

Liftable double nozzle | Good print quality | Complex structure, relatively expensive |

IDEX | Good print quality, can print two models at the same time | Many accessories, large size of the machine and high cost |

Dual extruder single nozzle | Lightweight,cheap | Sharing a nozzle, the switched filaments are easy to remain, resulting in uncontrollable mixing of the two filaments, the printing effect is not ideal, easy to make nozzle pluging |

Dual extruder mixed nozzle | Lightweight and cheap, it can realize the controllable mixing of two filaments | Sharing a nozzle, the switched filaments is easy to remain, causing the two filaments to mix together |

Best 3D Printer 2020 under $500

In summary, the dual extruder 3D printer is very advantageous. In our market research, most customers have not purchased the dual extruder 3D printer at present because of the high price and stability, that is, if one is stable and the price is cheap dual extruder 3D printer will be very popular. Therefore, we hope to have such a dual extruder 3D printer:

1 Liftable dual extruder: cheap and stable structure, and reduce machine volume, reduce machine cost and transportation cost (relatively IDEX);

2 Use DIY structure: Under the premise of ensuring perfect functions, it can greatly reduce the cost and transportation cost;

3 Single-nozzle and dual-nozzle switchable: By disassembling and assembling, it can switch between single-nozzle mode and dual-nozzle mode, which can improve the space utilization of the machine.

4 Expandable functions: According to customer needs in the later stage, the laser function and mixed nozzle function can be expanded;

5 Open source: Open the firmware code, so that everyone can expand according to their needs.

So, our company MakerPi (Shenzhen Soongon Technology Co., Ltd.) will develop and launch such a product, best 3D Printer 2020 under $500 let’s look forward it.